Melco (CPM) manufacture a large range of high-quality conveyor pulleys to SANS 1669 and international standards.

Size capacity: Diameters up to 1800mm. Face widths up to 5000mm long. Shafts up to 580 diameter and 6000 mm long.

Designs of pulleys can be verified using Finite Element Analysis (FEA) and are designed and selected for infinite fatigue life.

The design is for light to medium size pulleys up to a 200mm diameter shaft.

Using the 06 type single acting locking element connecting the shaft to the hub.

The end disc is shaped to allow for pressures and defection through the drum and shaft.

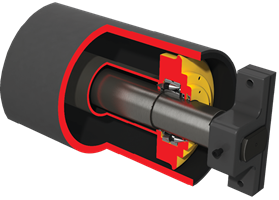

A heavy-duty range design common with all shafts over 200mm diameter

Using the 15 type double taper locking element connecting the shaft to the hub and are capable of handling larger tensions and angular deflections, especially drive torque on drive pulleys.

The solid end discs are profiled for even stress distribution on the pulley while in operation.

The weld area is relocated to the drum/rim, resulting in lower alternating fatigue stress in the entire drum.

Numerous lagging types are available, as required by the application and given specifications. Lagging is supplied according to SANS 1669 Part 2 and all international standards.

In flat or diamond grooving.

Various tile configurations. For drive pulleys.

GREASE FILLED/ STATIC SHAFT PULLEY

These pulleys are used in specialised situations and conditions where dirty conditions require a protected bearing.

Sizes limitation with a 400mm shaft and 360mm diameter bearing.

The L-Bottom end disc, locking element and stub shaft, make for a large pulley

that is light weight. Specifically for Belt Filters and similar applications.

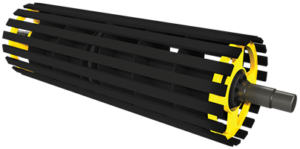

A range of “self-cleaning” and “self-tracking” conveyor pulleys are Manufactured such as Slatted, Cone Slatted, Wing, Spiral and Belt beating pulleys.