Melco manufactures a large variety of idler design configurations according to industry standards such as SANS 1313, DIN or CEMA or according to customer requirements.

Idlers are supplied for a standard range of belt widths from 450 mm to 2400 mm. Idlers are manufactured according to customer requirement as:

- 1, 2, 3 or 5 roll design

- Offset or inline

- Top mounted or underslung

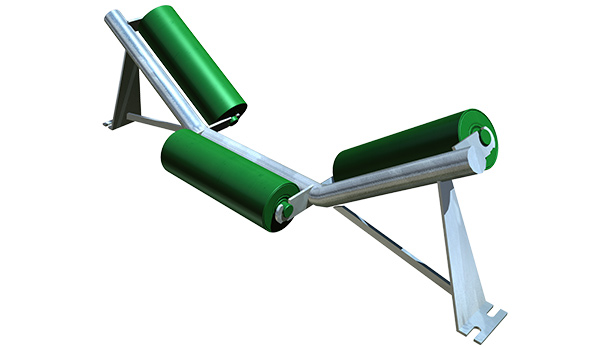

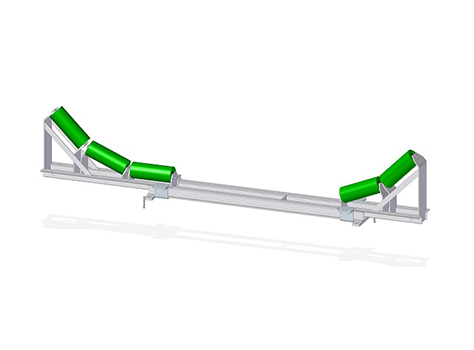

Troughing idler

3 Roll, offset, top mounted, tubular

Troughing idler

3 Roll, offset, underslug, tubular

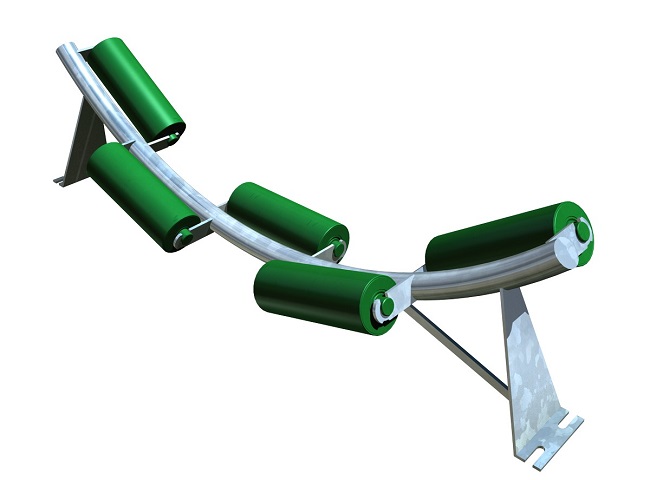

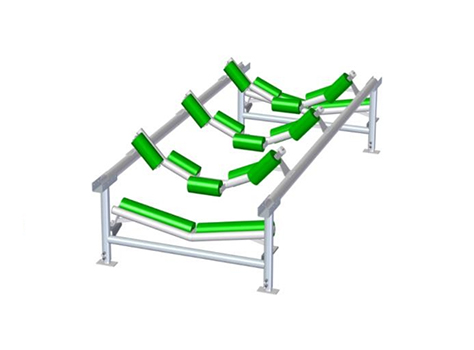

Troughing idler

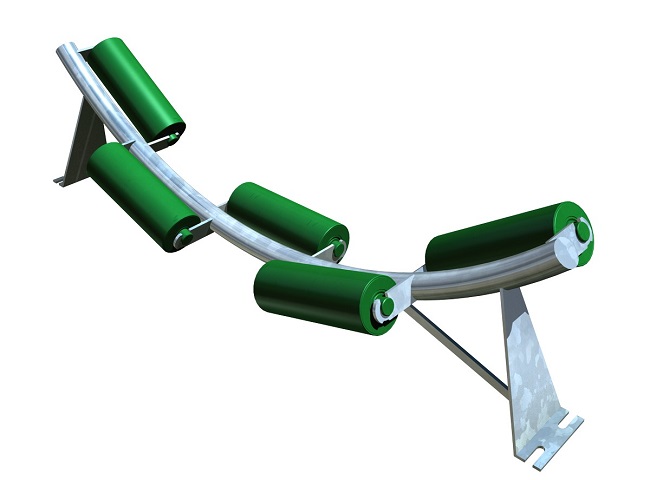

5 Roll, offset, top mounted, tubular

Troughing idler

3 Roll, inline, top mounted

Impact idler

3 Roll, offset, top mounted

Adjustable idler

3 Roll, inline, top mounted

Picking idler

3 Roll, offset, top mounted

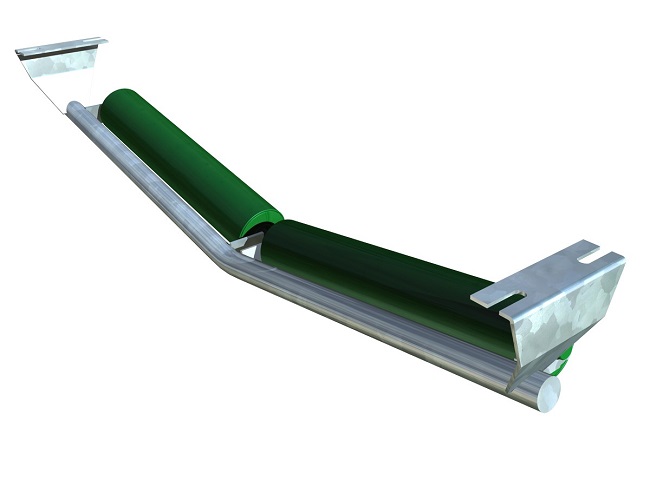

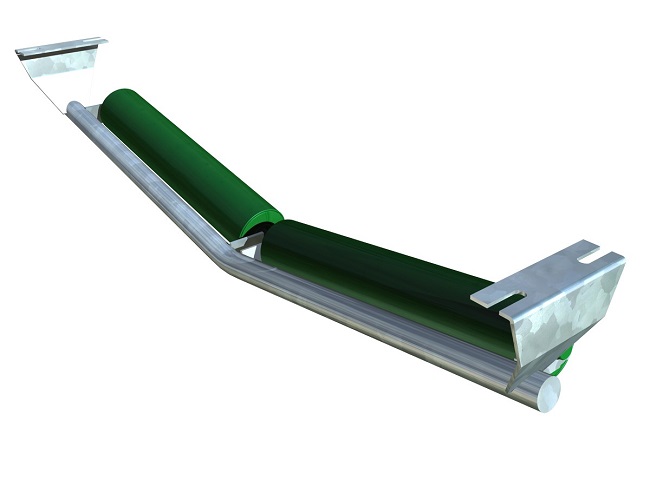

V-Return idler

2 Roll, inline

Troughing training idler

3 Roll, inline

In addition to standard idlers, Melco designs and manufactures numerous speciality idlers to meet client requirements.

Idler frames are designed to accommodate for the operational loading characteristics of the conveyor where the cross member is designed to ensure that the loading and deflection limits are met.

Frames are manufactured primarily using various tube or angle iron main cross member. The Melco Belt Saver idler frame uses tubular cross-sections to protect the belt in the event of a roller coming out of the frame.

Impact frames typically have a more sturdy design to accommodate for impact loads.

Frames are supplied as galvanized or standard painted. Special paint systems are also available for corrosive environments.

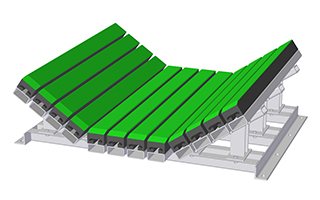

Impact beds

High impact bed – used for high impact onto belts. The garland impact strings and cushioning rubbers absorb the impact and protect the belt.

Slider bed

(Skega) – used for moderate impact loads. The belt slides on the rubber backed UHMWPE slider bars and allows belt to seal against skirtings.

Seal table

rubber backed UHMWPE slider bars on the wings allow for belt sealing against the skirtings and the centre impact rollers absorb impact onto the bed.

Various operating conditions of operation and requirements from clients can be accommodated in design.

Some of these solutions are noted below:

5 Roller configuration

For larger belts (> 1200 mm), a 5 roll carry design presents advantages over the 3 roll design. The total idler load is spread over 5 rollers and so the shaft/bearing specification of the roller can often be reduced. Saving costs and easing maintenance due to lower mass.

Tubular cross member

A frame’s cross member under load has a limit on deflection and maximum stress. Changing this cross member from a traditional angle iron section to a tube can save mass and costs.

Unequal roller

The center roller of an idler carries approximately 60% of the load. By using a shorter centre than the wing rollers, the roller shaft deflection is reduced meaning that the center roller can have a lower specification saving costs. This solution can be used in conjunction with a larger roll diameter on the center roller reducing belt drag over the idler.

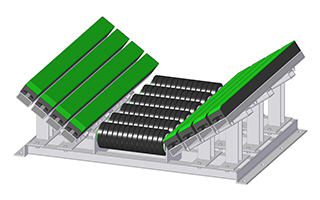

Banked idlers for overland conveyors

Long overland conveyors frequently need to navigate horizontal curves. In order that the belt follows these curves, the troughing and return idlers are banked.

Solutions for loading zones

Idler maintenance in loading zones can be difficult because of the presence of loading chutes that make the lifting of the belt difficult. Jack-down idlers and retractable idlers solve this problem:

Download our solutions for loading zones

Jack-down idler

Frame is lowered by means of bottle jacks in order to get clearance to change the rollers.

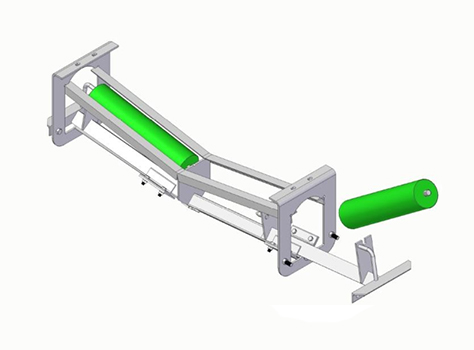

Retractable idler

Idler splits into two sections which retract horizontally to aid the changing of the rollers.

Retractable V-Return idlers

Changing return idler rollers beneath an inclined conveyor is difficult and dangerous.

The retractable V-return idler has a split frame that retracts into the walkway for easy changing of the rollers.

Modular structure

Melco manufactures modular conveyor structures used frequently in underground mines

For more information regarding Melco Frames

Fill in the form below and we will be in contact with you shortly